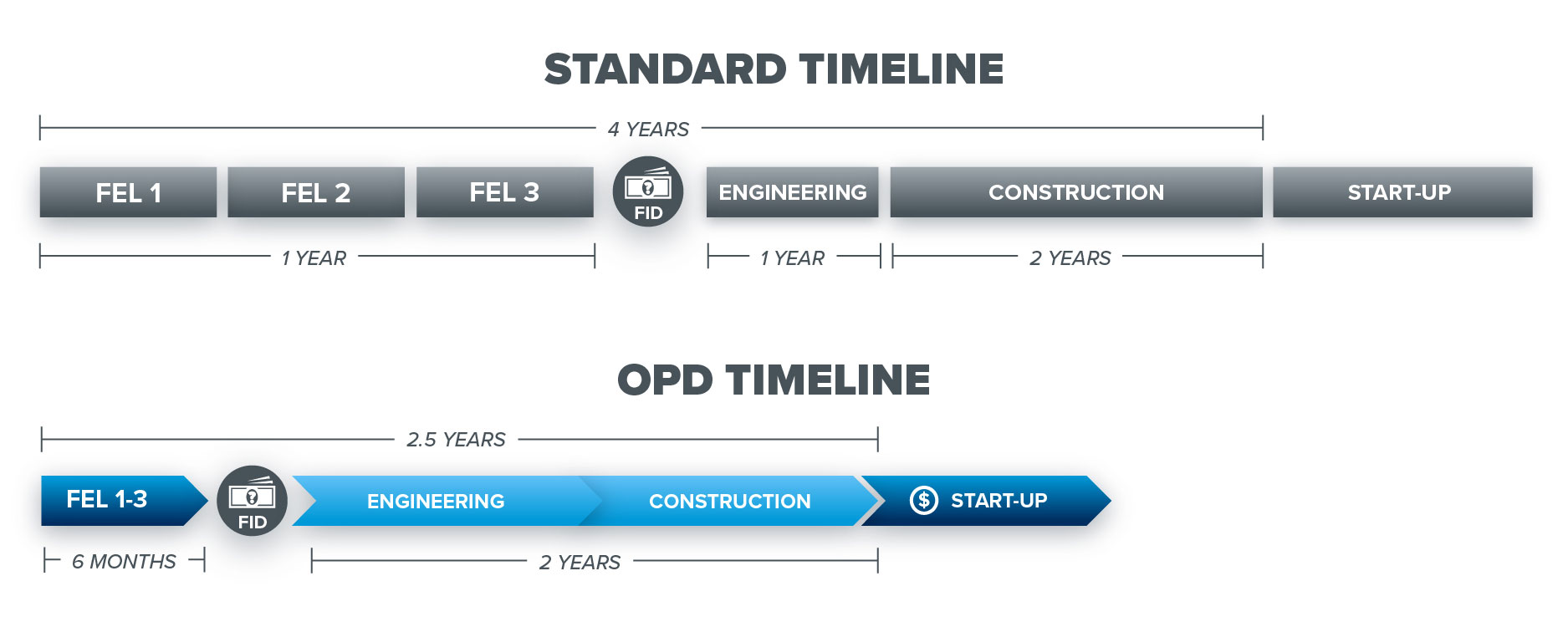

Accelerate Your Project

At OPD, we understand the importance of speed and efficiency when it comes to getting your project off the ground. That’s why we specialize in working through all FEL 1-3 stages quickly, without sacrificing on quality. You’ll be able to make an investment decision faster, giving you a head start on your competition and putting you on the path to success.

Optimized for Excellence

The true cost and schedule savings of working with OPD are realized when we fully execute a project from early-stage planning through start-up. From conceptual design to fabrication and warehousing, we deliver full EPC services with on-site leadership and OPD construction crews.

Engineering

Early-stage planning including FEED studies, project schedules and conceptual designs. Detailed engineering packages in all disciplines including design drawings, 3-D models and renderings. Disciplines include:

- Process

- Mechanical

- Civil/structural

- Instrumentation, electrical and controls

Procurement

OPD provides single-point procurement of all equipment, materials and construction services necessary to fabricate and construct our clients’ projects. Our large Katy, Texas, warehouse provides a central storage and distribution point, aiding in overall project logistics.

- Process equipment

- Piping materials

- Electrical materials

- Instrument materials

- Civil/structural materials

- Subcontract services

- Buildings

- Insulation

- Painting

- Post weld heat treatment (PWHT)

Fabrication

Our 33,000-square-foot fabrication shop and 30-acre site support fabrication of structural steel, carbon steel and alloy pipe spools, as well as ASME-coded vessels (U&R stamps).

- Carbon steel and alloy pipe spools

- ASME code-stamped pressure vessels

- Pressure vessel repairs and alterations per ASME/NBIC

- Process skid modules/skid assembly

- Structural steel supports and skids

- QA/QC

Construction

Our direct-hired field crews safely and efficiently perform the major phases of field construction, from initial site work to startup.

- Earth/site work

- Civil

- Structural

- Mechanical

- Electrical and instrumentation management

- Testing

- Commissioning

- Piping

- Sub-contract: I/E construction and soft crafts

Markets We Serve

Our highly experienced, in-house team can safely and efficiently execute projects in a range of industries including:

Emerging Markets

Carbon Capture

Hydrogen

Renewables

Lithium

Sulfuric Acid

Legacy Markets

Refining, Petrochemical and Industrial

- Propane dehydrogenation

- Isobutane dehydrogenation

- Hydrotreating

- Isomerization

- Ethermax (MTBE)

- Heavy oil (petroleum pitch)

- Revamps/turnarounds

Export Terminals

- Ethane

- Ethylene

- Propane

- Butane

Natural Gas and Liquids Processing

- NGL fractionation

- Cryogenic NGL recovery

- Gas sweetening

- Compressor stations

- Helium

- Specialized NGL separation

- Condensate handling

- Dew point control

Our work

Project Highlights

Learn about our recent projects.

Isobutane Dehydrogenation Unit

Learn about this project that totaled more than 2 million man-hours.

NGL Fractionator Unit

Learn more about this project that had 400 OPD personnel in the field at once.

Natural Gas Processing Facility

Learn more about this unique cryogenic expander plant project.